Anatomy of a Storage Drive: Hard Disk Drives

Information technology's magnetic. Information technology's electrical. It's photonic. No, this isn't going to exist well-nigh a new superhero trio in the Marvel universe. This is all near our precious digital information. We need to shop information technology somewhere secure and stable, in a fashion that lets us get concord of it and alter it faster than you can blink. Forget Atomic number 26 Man and Thor -- we're talking nearly storage drives!

Then let's prep for theatre, scrub our hands clean, and dig into the anatomy of what we utilize today to hold onto our trillions of digital bits.

Nosotros've split the Anatomy of a Storage Drive in iii parts, all published at the aforementioned time to dissect hard deejay drives, solid state storage, and optical drives. Follow the links below to read them all, along with our previous published piece of work on the serial.

You spin me right round, baby

Let'southward start our await into the guts of storage drives with ones that use magnetism to store digital data. The mechanical hard disk (HDD) has been the standard storage system for PCs across the world for over 30 years, simply the technology behind it all is much older than that.

IBM released the first commercially available HDD in 1956, all three.75 MB of information technology. And generally speaking, the overall structure hasn't inverse a great deal in that fourth dimension. There are nevertheless disks, that utilise magnetism to store data, and there are devices to read/write that data. What has inverse, and hugely so, is the corporeality of information that can be stored on them.

Back in 1987, you could buy a 20 MB HDD for around $350; today that kind of money will get you xiv TB of storage: 700,000 times more infinite.

We're going to take autonomously something that'southward non quite that size, but still pretty decent today: a 3.5" Seagate Barracuda three TB HDD, specifically the ST3000DM001 model, infamous for it's high failure rate and subsequent lawsuits. This one is dead, too, so in truth this is more of an autopsy, rather than an anatomy lesson.

The bulk of the hard bulldoze is bandage metal. The forces inside the device, when nether heavy usage, can exist pretty serious, so the use of thick metal stops the body from flexing and vibrating. Fifty-fifty tiny 1.viii" HDDs utilize metal for the body, although they tend to be fabricated from aluminum, rather than steel, equally they're designed to be as calorie-free as possible.

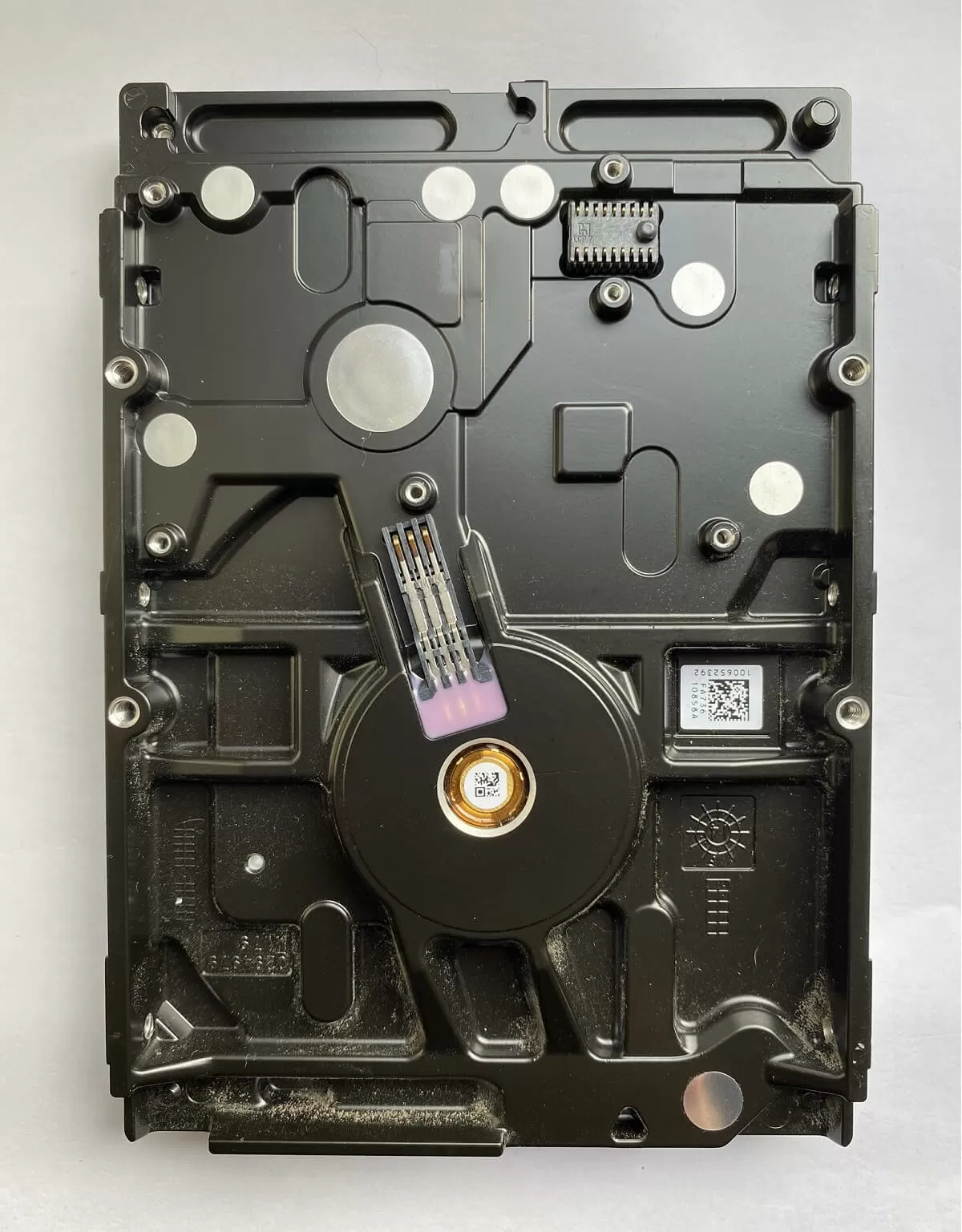

Flipping the drive over, we can see a circuit board and a bunch of connections. The one at the top of the board is for the motor that spins the disks, whereas the lesser three are, from left to right, jumper pins to allow the bulldoze to be configured for sure setups, SATA (Serial ATA) information, and SATA ability.

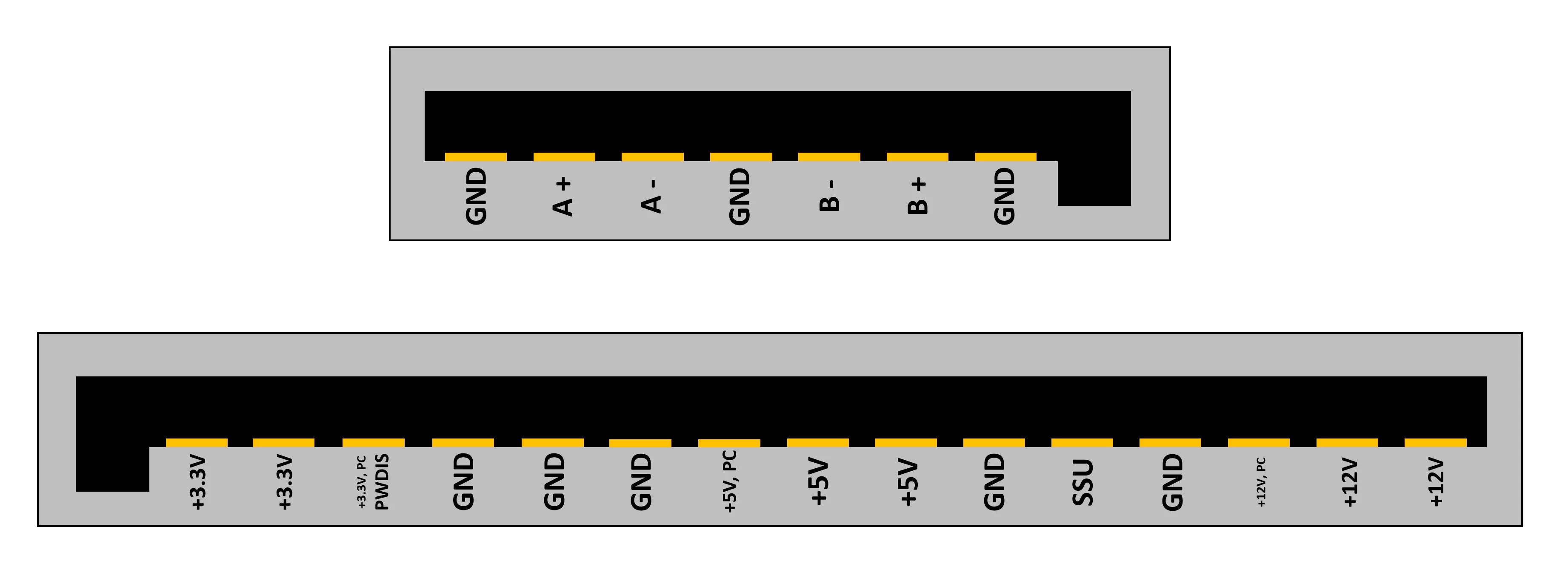

Series ATA first appeared in 2000, and in desktop PCs, it's the standard system used to connect drives to the rest of the figurer. The specification of the format has gone through lots of revisions since then and we're currently on version 3.4. Our hard bulldoze cadaver, though, is an older version only this just affects a single pivot in the power connexion.

The data connections use what is called differential signalling to send and receive data: the A+ and A- pins are used to transmit instructions and information to the hard drive, whereas the B pins are used to receive those signals. The use of paired wires like this greatly reduces the impact of electrical noise in the betoken, which ways it can be run faster.

On the power side of things, you can see that at that place are essentially ii of every voltage (+3.3, +5, and +12V); most aren't used, though, as HDDs don't need a lot of power. This particular Seagate model uses less than 10W under heavy load. The power pins labelled with PC are pre-charge ones: it allows the hard bulldoze to exist pulled in and out, while the computer is still on (a.k.a. hot swapping).

The pivot labelled PWDIS allows for remote resetting of the hard drive, but this is only supported by SATA version 3.3; so in our drive, information technology'due south just another +3.3V line. And the terminal pin to cover, the one marked SSU, just tells the calculator as to whether or not the hard bulldoze supports staggered spin upward.

The disks within the device -- which we'll run into in a few moments -- must exist spun upward to total speed before the estimator can start using it, simply if the car had lots of hard drives, the sudden simultaneous demand for power might upset the organisation. Staggering the spin ups helps prevent such problems ever occurring, but it does mean that you'd need to expect a few second more before you lot can get all jiggy with the HDD.

Removing the circuit board reveals how the circuit board connects to the components within the drive unit. HDDs aren't air tight, except for the super large capacity ones -- these use helium, instead of air, every bit it much less dense and creates fewer problems for drives with lots of disks. But you lot don't want them openly exposed to the surroundings either.

By using connectors like this, it helps minimize the amount of entry points that dirt and grit tin work their way into the drive; there is hole in the metal case - bottom left of the higher up image (large white dot) - to let air pressure to remain relatively ambient.

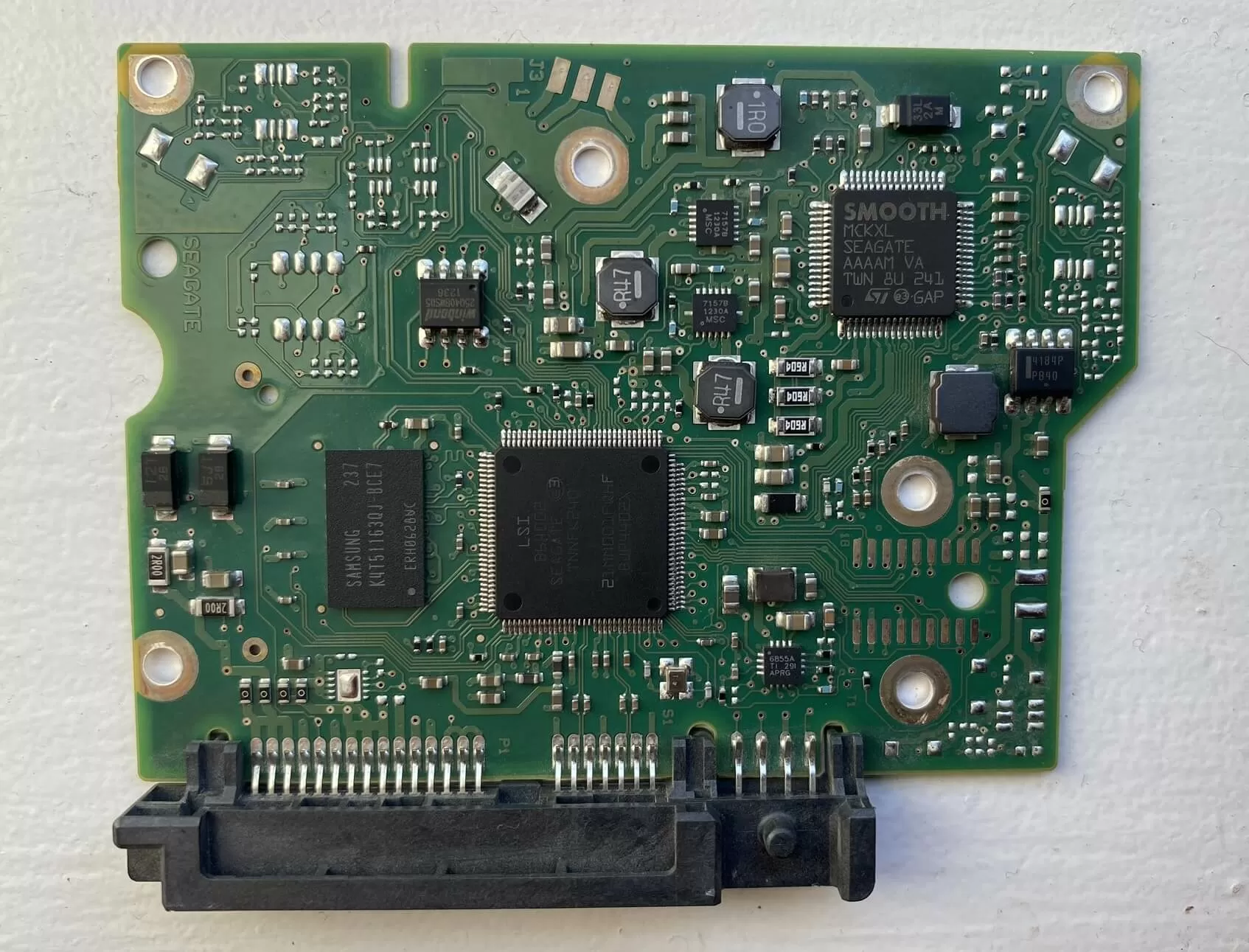

Now that the circuit board is off, let's have a wait at what'south here. There are 4 main fries to focus on:

- LSI B64002: the principal controller chip that handles the instructions, information flow in and out, error correcting, etc.

- Samsung K4T51163QJ: 64 MB of DDR2 SDRAM, clocked at 800 MHz, used to enshroud data

- Smooth MCKXL: controls the motor that spins the disks

- Winbond 25Q40BWS05: 500 kB of Series Flash retentivity, used to store the drive'due south firmware (fleck similar a PC's BIOS)

At that place's little difference across the vast range of HDDs out there, when it comes to the components on the circuit board. Larger storage requires more than cache (you lot can find upward to 256 MB of DDR3 on the latest monsters) and the main controller flake might exist a little more than sophisticated with regards to handling errors, just there's not much in it.

Opening up the drive is easy enough, simply unscrew a bunch of Torx fittings and voila! We're in...

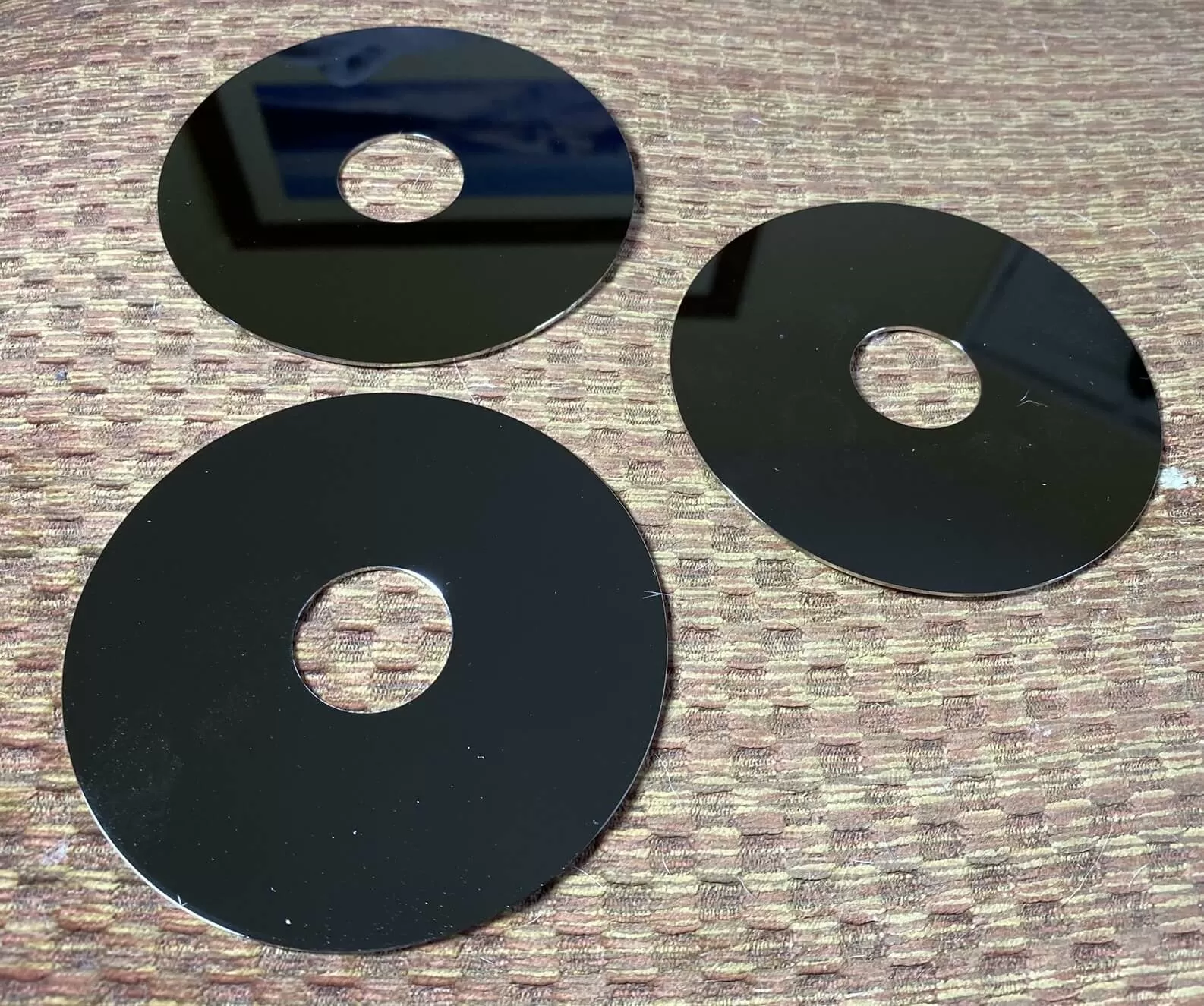

Given that information technology takes upward most of the unit, our attending is immediately fatigued to the big metal circumvolve, so it'due south not difficult to see why they're called disk drives. The proper name for them is a platter and they are made of glass or aluminum, coated with multiple layers of different compounds. This 3 TB drive has three platters, so each one must store 500 GB on each side.

The image of these dusty, hairy platters doesn't do whatever justice to the engineering and manufacturing precision required to produce them. In our HDD instance, the aluminum disk itself is 0.04 inches (ane mm) thick, simply it has been polished to such a caste that the average superlative of the variations in the surface is less than 0.000001 inches (roughly thirty nm).

A base layer of simply 0.0004 inches (10 microns) deep, comprising several layers of compounds, has been applied to the metallic. This is done through electroless plating and and so vapor deposition, which preps the deejay for the crucial magnetic material that's used to shop the digital information.

This material is unremarkably a circuitous alloy of Cobalt and is set out in concentric rings, with each i beingness effectually 0.00001 inches (roughly 250 nm) wide and 0.000001 inches (25 nm) deep. On the microscopic scale, metal alloys form grains, like soap bubbling floating on water.

Each grain has its ain magnetic field, but it can exist aligned into a prepare direction. The grouping of these fields gives rising to the 0 and one $.25 of data. If you want a deeper technical dive into this topic, have a read of this document from Yale University. The concluding coatings are a layer of carbon for protection and and so a polymer to reduce contact friction. Together, they come to no more than 0.0000005 inches (12 nm) thick.

Nosotros'll encounter why the platters take to be made to such high tolerances in a moment, merely information technology is amazing to think that, for as trivial as $fifteen, yous tin can be the proud possessor of nanometre-scale manufacturing!

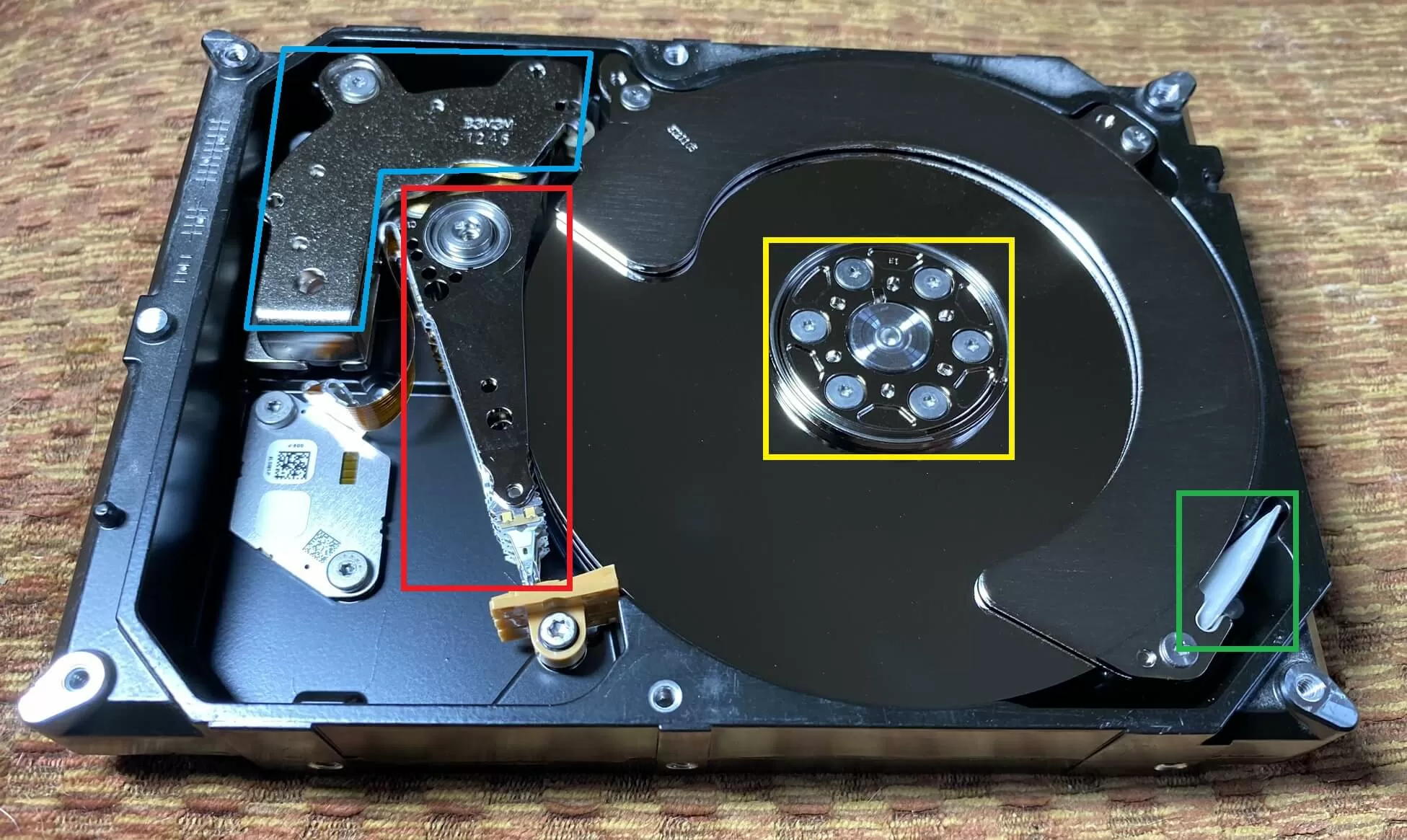

Let'due south become back to the whole HDD again, and have a await at what else is in that location.

The yellow box highlights a metal cap that holds the platter firmly in place on the spindle motor -- the electric drive that rotates the disks. In this HDD, they rotate at 7200 rpm, just other models run slower. Slower drives keep noise and energy consumption down, just also lowers functioning, while other faster drives can reach 15,000 rpm.

To help reduce the damaging effects of dust and wet in the air, a re-circulation filter (light-green box) picks upwards tiny particles and traps them inside. The air moved past the rotation of the platters ensures in that location is a abiding flow over the filter. On top of the disks, and next to the filter, is one of iii platter separators: these aid reduce vibrations and likewise proceed the air flow as regulated as possible.

In the meridian left of the image, indicated by a blue box, is i of 2 permanent bar magnets. These provide the magnetic field that is needed to movement the component highlight in cerise. Permit'south clear out some of these parts to come across this better.

What looks like a chunky Band Assistance is another filter, except this 1 clears out particles and gases from the outside, as they enter through the pigsty we see before. The metal spikes are actuator arms that hold the hard drive read/write heads - they sweep back and forth across the surface of the platters (superlative and bottom) at a ridiculously high speed.

Watch this video courtesy of The Slow Mo Guys to see just how fast it is:

Rather than use something like a stepper motor, to snap the arms into place, an electric electric current is sent around a coil of wire at the base of the arm.

These are generally called voice coils, considering it's the same principle that loudspeakers and microphones use to movement the soft cones. The current generates a magnetic field around it, which reacts confronting the field made past the permanent bar magnets.

Don't forget that the data tracks are tiny, so the positioning of the arms needs to exist extremely accurate -- just like everything else in the drive. Some hard drives have multi-stage actuators, that can do smaller changes in direction with simply part of the whole arm.

On certain difficult drives, the data tracks actually overlap each other. That technology is called shingled magnetic recording, and the requirement for accuracy and precision (i.e. hitting the correct position over and over) is even greater.

At the very ends of the arms are the delicate read/write heads. Our HDD has 3 platters and 6 heads, and each one floats higher up the disk as it spins. To exist able to practice this, the heads are suspended by 2 ultra thin strips of metallic.

Information technology'due south here that we can see why our anatomy sample is dead -- at least one head has come loose and whatever caused the original harm, also bent some of the support arms. The whole head component is so small-scale, that it's really difficult to get a skilful prototype with a regular photographic camera, as we can come across below.

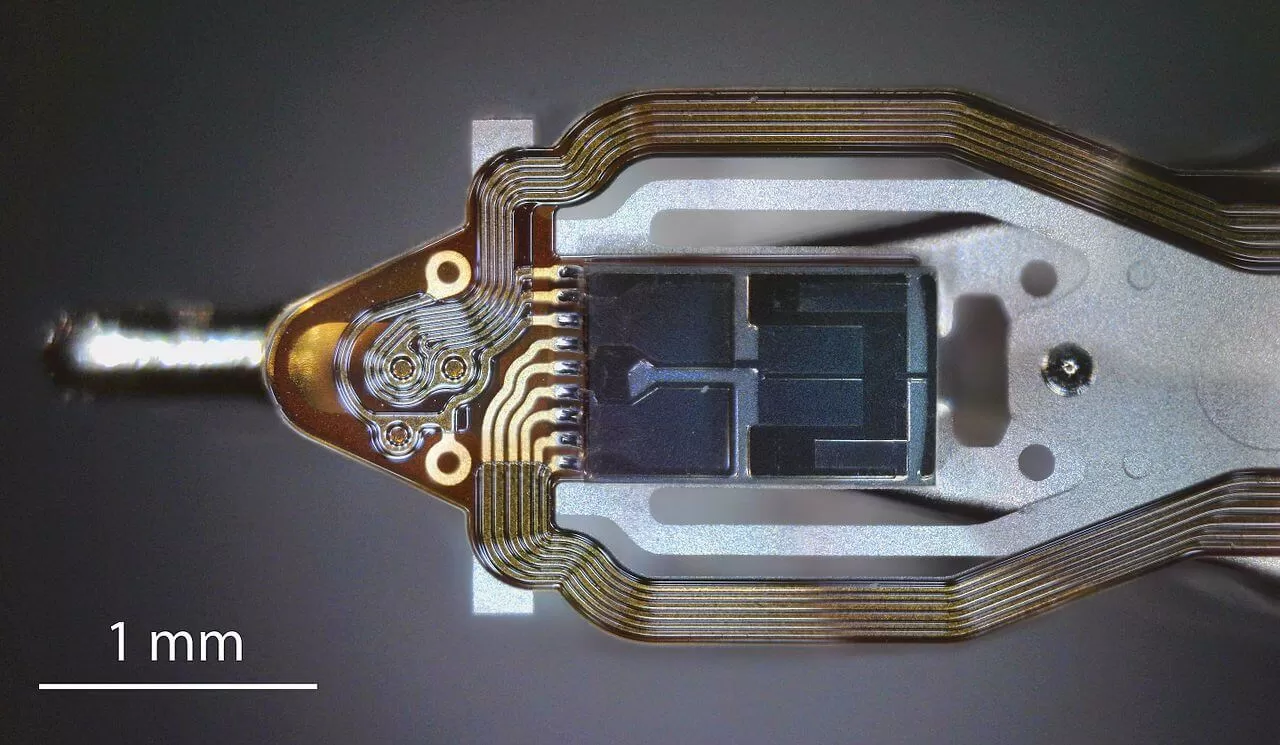

Nosotros tin make out some parts though. The greyness block is a specifically machined part called a slider, every bit the disk rotates underneath information technology, the flow of air produces lift, raising the head off the surface. And when we say "off," we're talking near a clearance of simply 0.0000002 inches or less than 5 nm.

Any further away and the heads wouldn't be able to observe the changes in the magnetic fields in the track; if the heads actually rested on the surface, they would just scrape off the coating. This is why the air inside the drive case needs to exist filtered: dust and moisture on the disk surface would but wreck the heads.

The tiny metal 'pole' at the end of the head is in that location to help with the overall aerodynamics. We demand a better motion-picture show, though, to see the parts that do the actual reading and writing.

In the above image, from a different hard drive, the parts that read and write are underneath all the electric traces. Writing is washed with an thin moving pictureconsecration(TFI) arrangement, whereas reading is done with a tunnelingmagnetoresistive (TMR) device.

The signals produced past the TMR are very weak and accept to exist run through an amplifier, to boost the levels, earlier they can be sent onward. The scrap responsible for this tin be seen nigh the base of the actuator arms, in the prototype below.

As mentioned in the introduction of this commodity, the mechanical components and functioning of a hard disk drive drive haven't changed a lot over the years. It's the technology behind the magnetic track and the read/write heads that has improved the most, producing narrower and denser tracks, which ultimately results in more than storage capability.

All the same, mechanical hd drives accept clear operation limitations, It takes time for the actuator arms to move to the required position and if the information is scattered about in different tracks on dissever platters, and so the drive will spend a relatively large number of microseconds hunting down the bits.

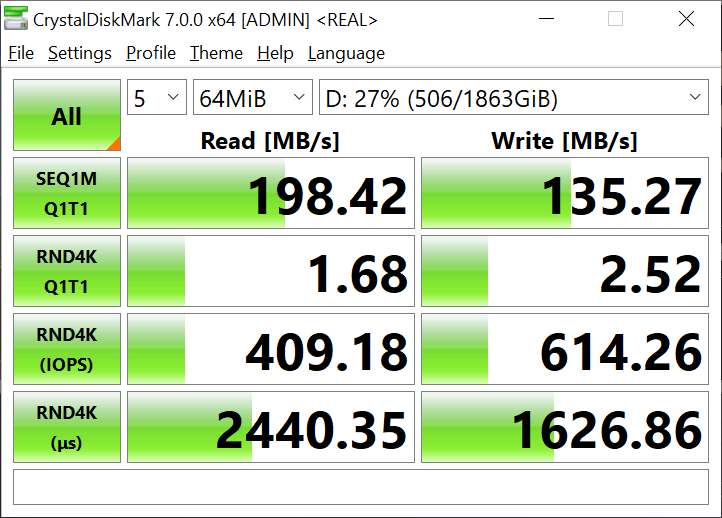

Earlier we move on to pull autonomously some other type of storage bulldoze, permit'south make a reference point for the performance of a typical HDD. We've used CrystalDiskMark to benchmark a WD 3.v" 5400 RPM ii TB hard bulldoze:

The first two rows display the number of MB per second throughput for doing sequential (a long, continuous list) and random (jumping near the disk bulldoze) reads and writes. The next row, shows an IOPS value, that'south the number of input/output operations taking place each second. The concluding row displays the average latency (time in microseconds) between the read/write functioning being issued and the data value beingness retrieved.

Generally speaking, you want the values in the outset three rows to exist every bit big as possible, and the concluding row to be equally small as information technology tin can be. Don't worry near the numbers themselves, it'southward just something nosotros'll utilise for comparison, one time we look at the next type of drive: solid country storage.

Keep reading the Anatomy of SSDs here.

Shopping Shortcuts:

- Seagate BarraCuda 8TB HDD on Amazon

- WD Red 14TB NAS Hard Drive on Amazon

- Seagate Fill-in Plus Hub 8TB External HDD on Amazon

- Seagate IronWolf 8TB NAS HDD on Amazon

- Synology DiskStation DS418play iv-bay NAS on Amazon

- QNAP TS-451+ iv-Bay NAS on Amazon

Masthead credit: Patrick Lindenberg

Source: https://www.techspot.com/article/1984-anatomy-hard-drive/

Posted by: kennardengstiong.blogspot.com

0 Response to "Anatomy of a Storage Drive: Hard Disk Drives"

Post a Comment